Ready Mix Truck Integral Concrete Coloring 18 Colors SurePour™

Our 10-pound ready mix new concrete colors bags provide the contractor with a light, fast, weather-resistant, lime-proof, no maintenance finished product. SureCrete Design Products maintain the highest tinting qualities with strength and color material consistency from bag to bag. In our manufacturing plants, color is conveniently packaged in a disintegrating bag that disperses safely and rapidly into the cement concrete batch, making it better than most ready-mix color companies in the market today. Avoid a sign discolorations concrete by sealing your concrete with a high-quality sealer.

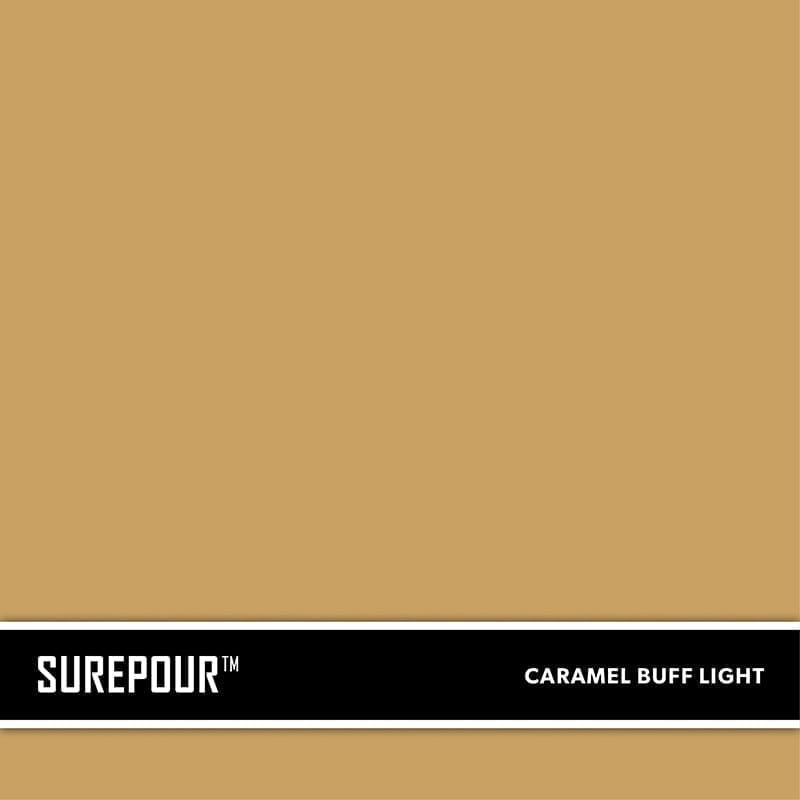

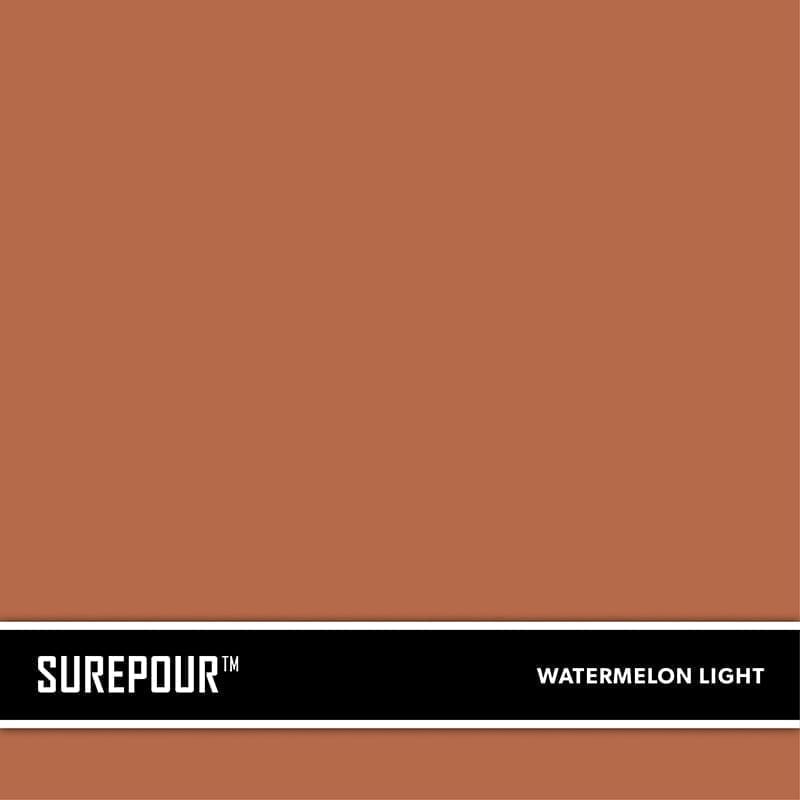

Light = 1 Bag Color / 2 Yards Concrete

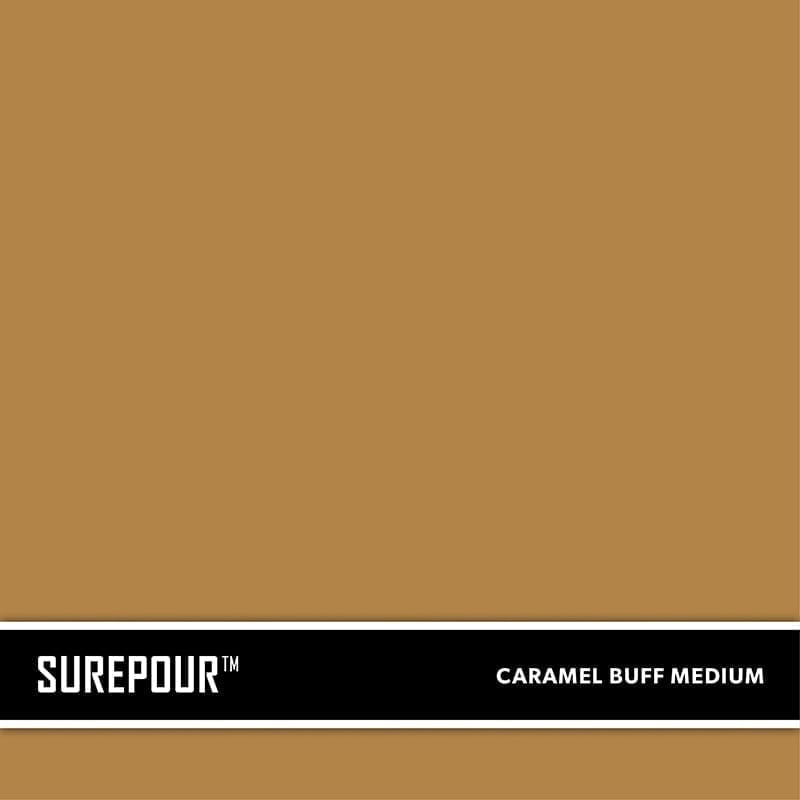

Medium = 1 Bag Color / 1 Yard Concrete

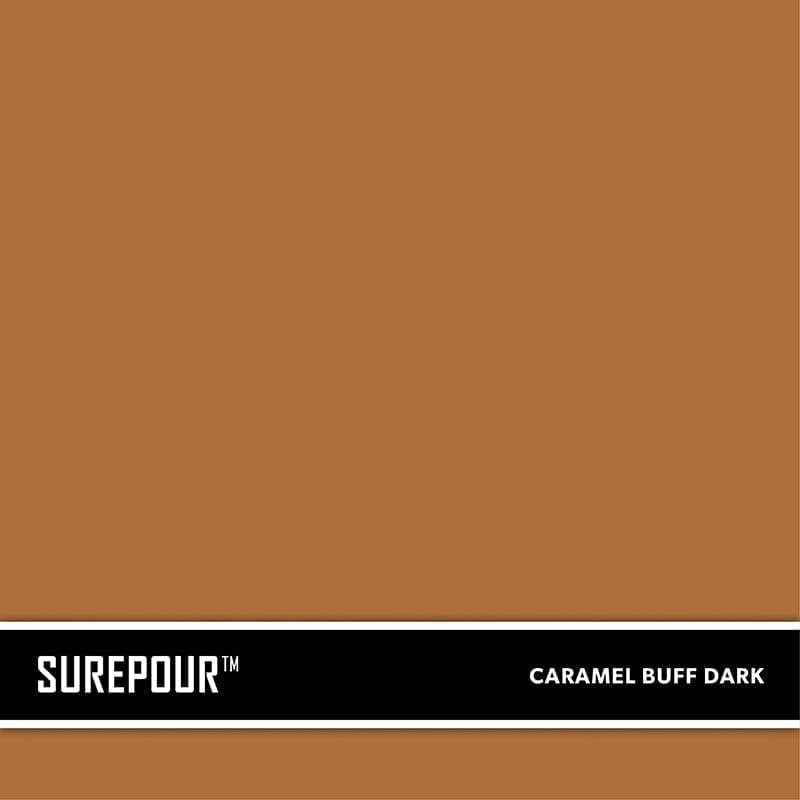

Dark = 2 Bags Color / 1 Yard Concrete

DATA SHEET DOWNLOADS

New Concrete Color Integral Coloring 18 Standard Colors

Integral Color has been used for years to enhance the look and design of concrete surfaces and has been formulated in both liquid and powder dispersal. The idea behind Integral Color is to tint or pigment an entire slab of concrete directly at its source, which is perfect for large themed areas such as outdoor tennis and basketball courts, build theme parks and recreational facilities that win awards.

Our Integral Color contains only finely milled synthetic iron oxides, the strongest and most stable colors available. These colors are lime-proof, sun fast, inert, and meet or exceed the

criteria of ASTM C979.

Our custom formulated colors can cover the entire spectrum upon your request. Each color match is handled on an individual basis. In cases where exact color matching is required,

samples of your field raw materials may be required for sample preparation.

SureCrete’s Integral Color bags dry colorant, not a liquid is available in specially designed packages for your on-site use. Because of the inherent tinting strength of synthetic iron oxides, standard loadings do

not exceed 4%. Levels greater than 5% will not enhance the finished color.

Some areas that utilize SurePour™ Concrete Integral Color:

- Fresh Poured Concrete Slabs

- Stamped Cement Floors

- Patios and Pool Decks

- Alternative to Liquid Colors

- New Cure Concrete Color

- Cocnrete Home Driveways

- Color Surface Concrete

- Outdoor Kitchens

- Exterior Commercial Floors

- Themed Restaurant and Bars

- Integral Concrete Colorant

- Fresh Poured Concrete Driveway

- Concrete Decorative Colorant

- Concrete cures with colorant in it

Installers Support Questions:

How Do You Apply SureCrete's Ready Mix Integral Color Sacks Tinting Powder?

How to Mix Concrete Integral Color:

Step 1. Since the bags that contain Integral Color are bio-degradable curing colored, the entire bag can be thrown in your mixing truck and blended along with the concrete mix.

Step 2. Integral Color can also be portioned out into smaller increments based on your desired mix ready concrete color load.

Step 3. Seal for non-discoloration.

HOW AND WHERE TO USE SURECRETE’S NEW CONCRETE COLORING ADDITIVE

- Sub-Grade

A successful concrete slab starts with a well-drained sub grade that can uniformly sustain the weight of the slab as well as the load imposed on the slab. The subgrade should be uniformly graded compacted and thoroughly dampened. There should not be any soft or muddy spots or freestanding water on the subgrade. - Placing

Integral colored concrete does not require special procedures for placing and finishing. However, greater care and good concrete practices must be followed. All stained concrete should be put at the same slump, using the lowest slump consistent with a workable and placeable

mix. A 3”-4” slump is recommended, 5” maximum. Once a portion of the batch has been placed, no water should be added to the remaining batch. Concrete should always be put in the forms as near the final location as possible. The movement should be minimal, as it encourages segregation. Be sure to cover all nearby slabs and structures to avoid spatters from the new colored concrete. - Cures Colored Concrete Finishing

For color, uniformity finishing should be done carefully. Do not over trowel, as this will cause dark spots from tool burning. Finishing must not begin until bleed water has left the surface to avoid severe scaling, dusting, crazing, efflorescence, or uneven coloring. No dusting of cement or sprinkling of fogging water should be used when finishing colored concrete. A broom, rotary, or textured finish is recommended - Placement of Vertical Concrete

Planning is crucial in the placement of vertical and poured-in-place concrete. Consider the type of cement, detailing of formwork, mixing and placing techniques, slump control, and temperature of cure. It is recommended that a field mock-up panel is prepared. Include all materials, reinforcing steel as in the finished product. - Design Criteria for Colored Concrete

The following points should be considered in designing colored concrete. The concrete temperature should be between 65 and 85 degrees. The timing of the arrival of concrete trucks is crucial so that there is no excessive mixing. Avoid using porous forming materials. Conveying methods must be consistent with ACT-304- 73. The concrete should be deposited in the level lifts 12-18” thick. The distance between intersections should be about 18” depending on the concrete mix and vibrator used. Tilt-up concrete panels should be textured using sandblasting and surface retarders to expose coarse aggregate based on sealer color, water sealers or solvent based. - Patching Colored Concrete

Doing repair work within two days to minimize color variation? The same materials and methods should be used. A 50/50 mix of white/gray cement can be used to compensate for the darker patch area. The same color loading should be utilized on all repairs. - For Central Mix or Mixed Batch Plants

Add 1/2 (one-half) of the total batch into a clean ready mixed truck drum. Do not use slurry water or reclaimed aggregates. Insert the correct number of disintegrating bags into the drum and mix at high speed for at least 3 minutes. Batch the remaining concrete into the truck and mix again for at least 3 minutes before final slump adjustment. At the job site, remix the load for at least 3 minutes to ensure concrete consistency. Do not exceed maximum allowable revolutions. - Additional Considerations for Consistent Color

Color loads should never be smaller than three cubic yards. Add reinforcement fibers after the color load has been thoroughly mixed. This reduces the potential for fiber color balling. Use one source for cement, aggregate throughout out the job. Monitor and control incoming material consistency. Do not use calcium chloride-based admixtures. Wash out all drums before loading. Keep slumps consistent. Minimize driver-added water. A 3 to 5-inch slump is recommended. Maintain the same water/cement ratio. Required higher slumps should be achieved by using water reducing of plasticizing admixtures and NOT by adding water because this will adversely affect the color and sealers water based.

CAUTIONS:

KEEP OUT OF REACH OF CHILDREN. Inhalation: Avoid prolonged breathing of airborne dust, particularly present during mixing. Use NIOSH approved respirator for nuisance if threshold limit values are unsafe. Skin Contact: Skin contact

may cause irritation. Remove contaminated clothing and wash affected skin with soap and water. Launder clothing before reuse. If symptoms views persist, seek medical attention. Eyes: Wear safety eye protection when applying. Contact with eyes may cause irritation. Flush eyes with water for 15 minutes. If symptoms persist, seek medical attention.

SurePour™ Ready Mix New Concrete Color Sacks Part Numbers SKU’s and UPC’s

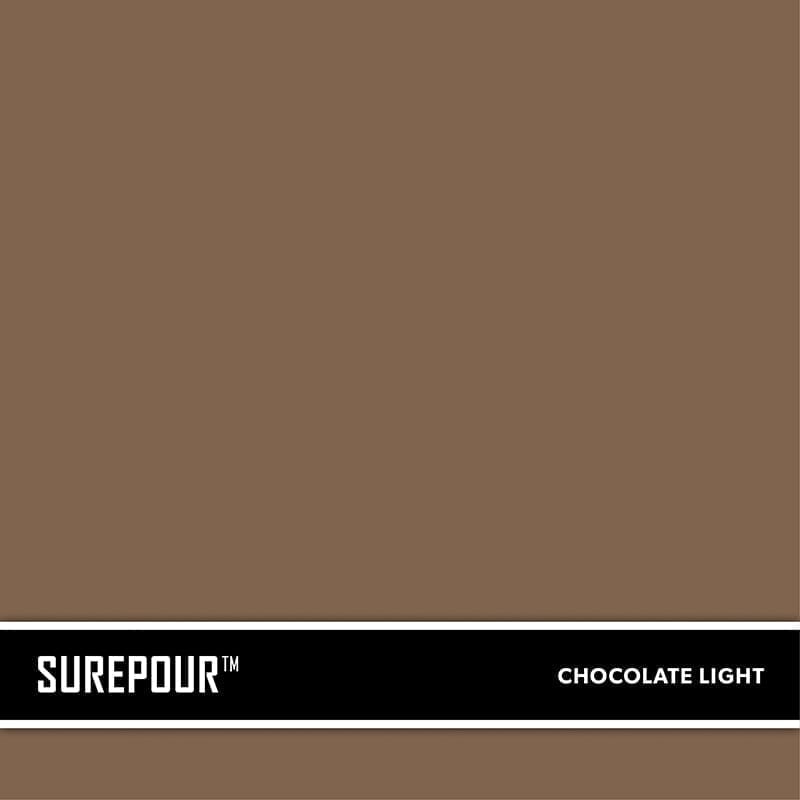

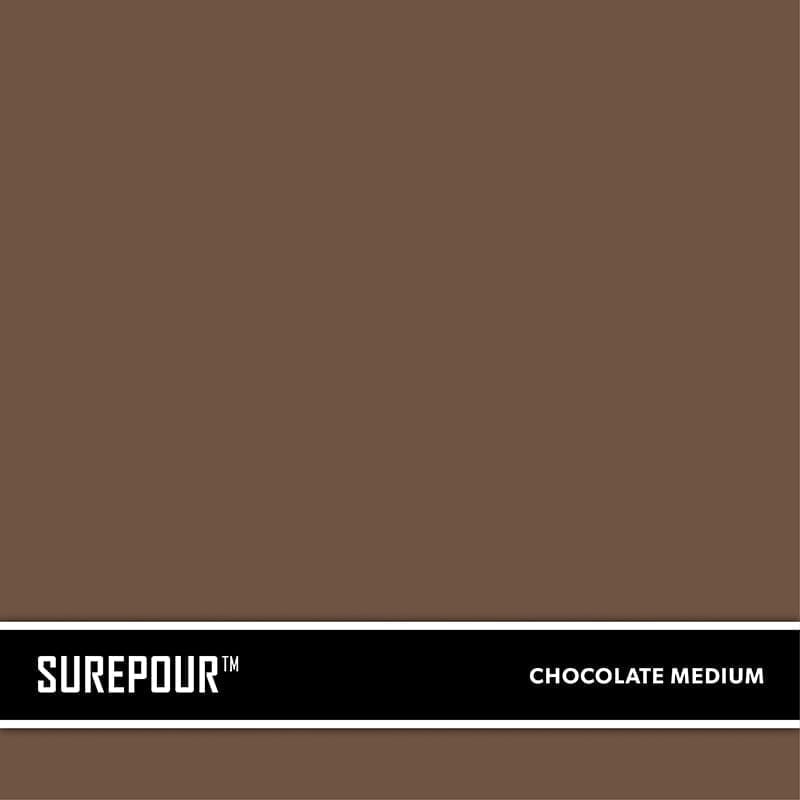

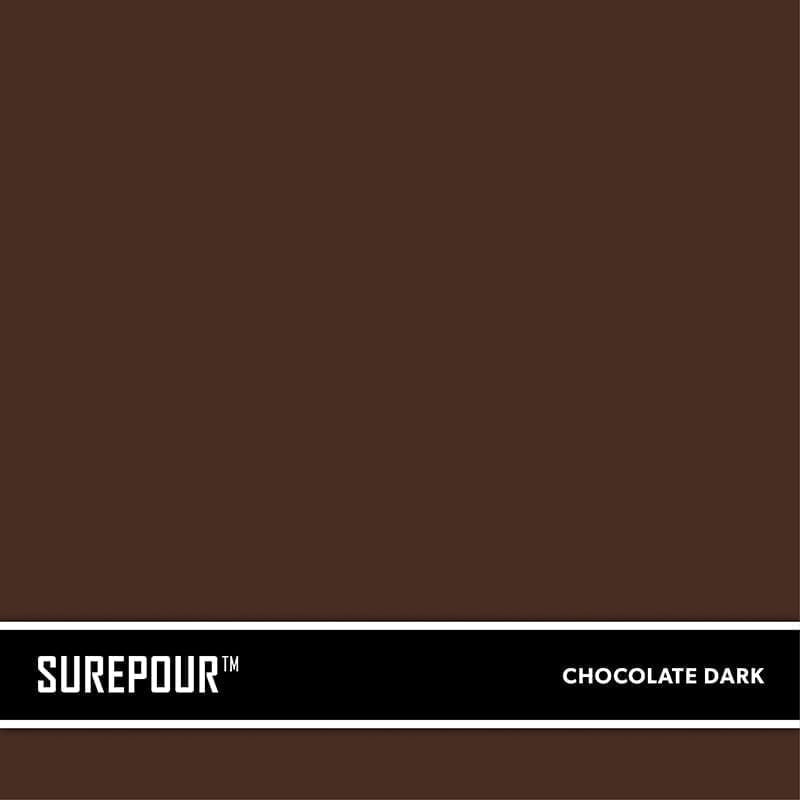

Light Chocolate (1/2 Bag) Per Yard SKU: 35103008-07-L | UPC: 842467100684

Chocolate (1 Bag) Per Yard SKU: 35103008-07 | UPC: 842467100691

Dark Chocolate (2 Bags) Per Yard SKU: 35103008-07-D | UPC: 842467100707

Light Caramel Buff (1/2 Bag) Per Yard SKU: 35103008-73-L | UPC: 842467100714

Caramel Buff (1 Bag) Per Yard SKU: 35103008-73 | UPC: 842467100721

Dark Caramel Buff (2 Bags) Per Yard SKU: 35103008-73-D | UPC: 842467100738

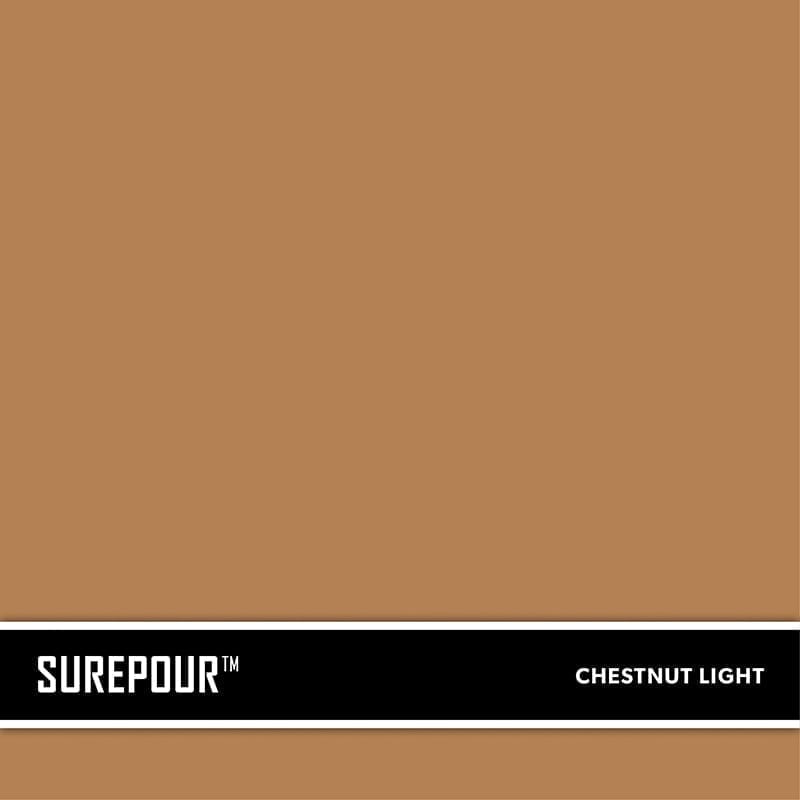

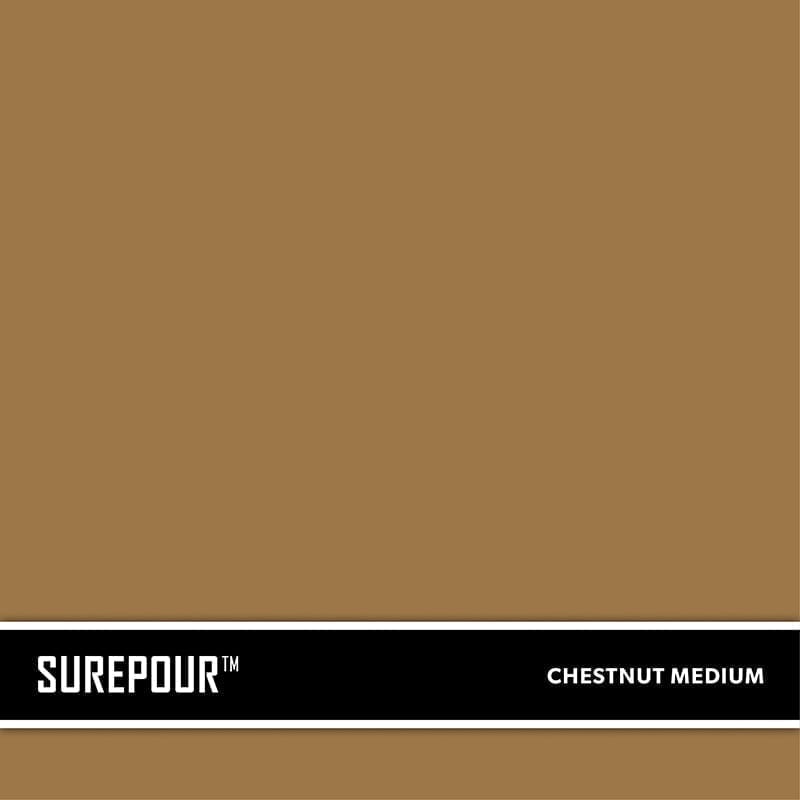

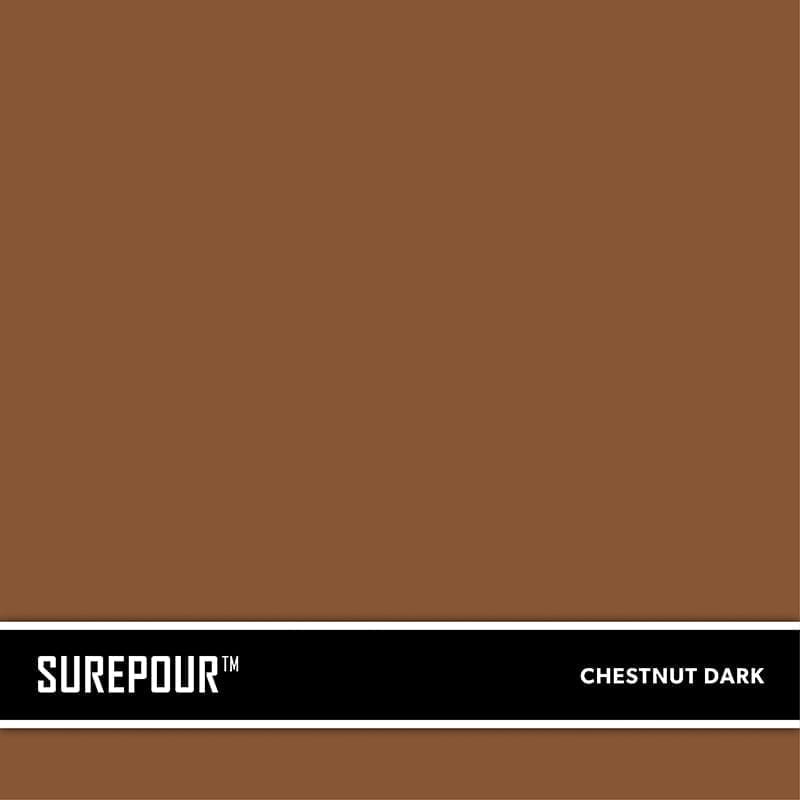

Light Chestnut (1/2 Bag) Per Yard SKU: 35103008-74-L | UPC: 842467100745

Chestnut (1 Bag) Per Yard SKU: 35103008-74 | UPC: 842467100752

Dark Chestnut (2 Bags) Per Yard SKU: 35103008-74-D | UPC: 842467100769

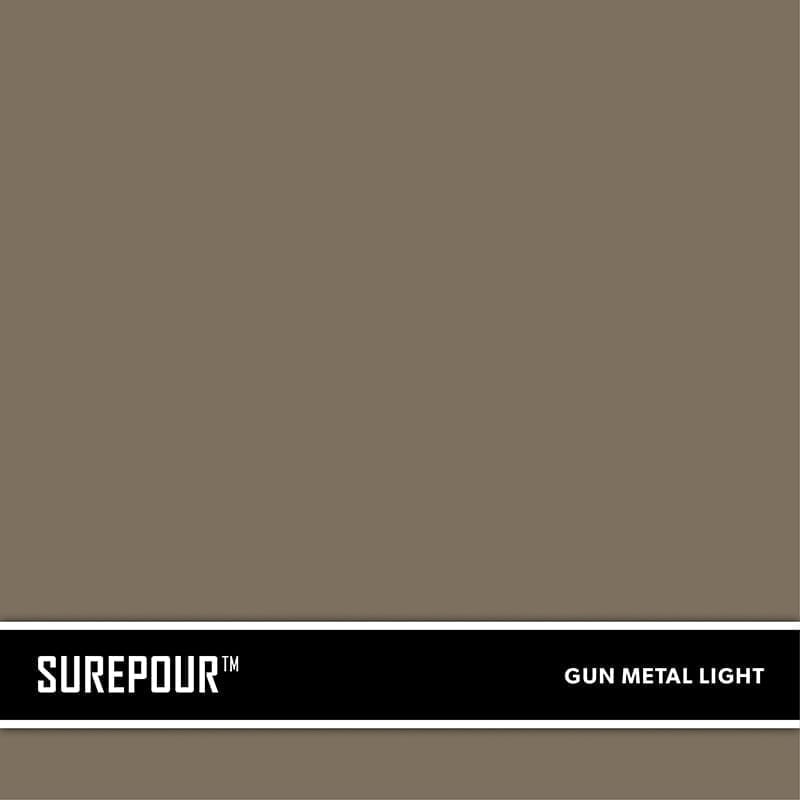

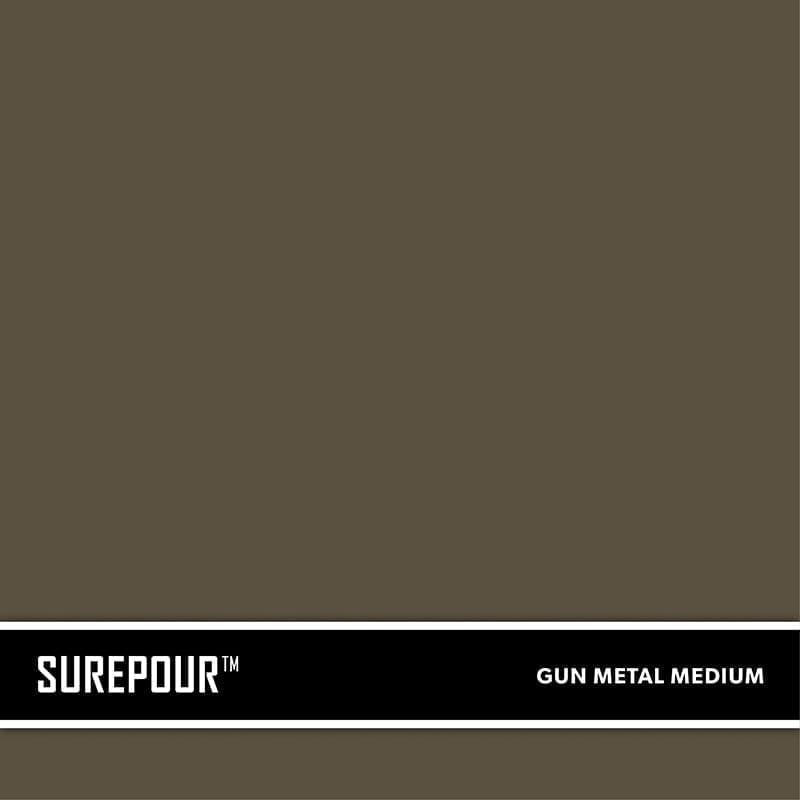

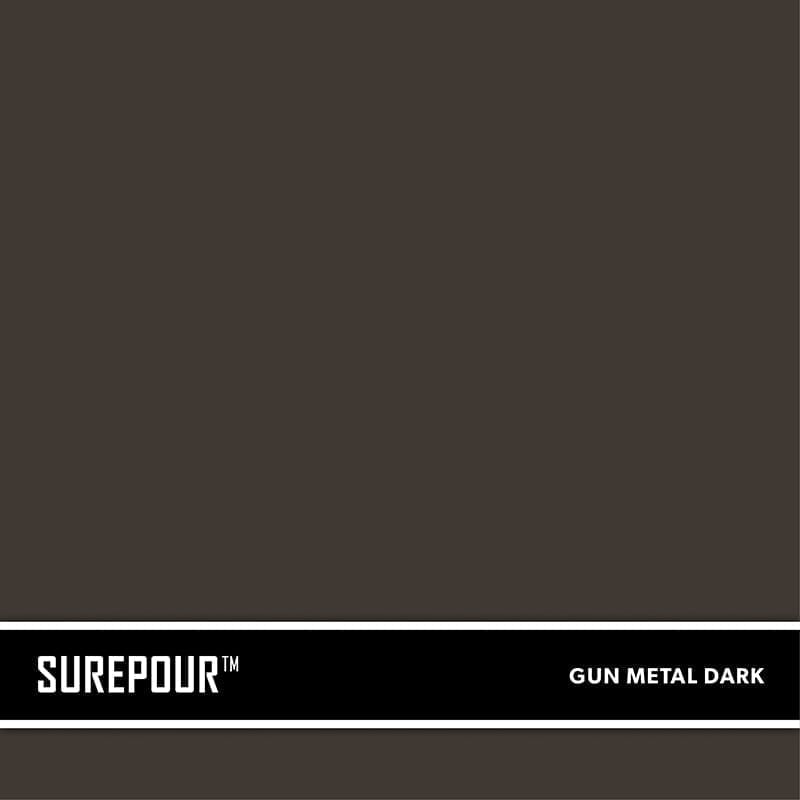

Light Gun Metal (1/2 Bag) Per Yard SKU: 35103008-81-L | UPC: 842467100776

Gun Metal (1 Bag) Per Yard SKU: 35103008-81 | UPC: 842467100783

Dark Gun Metal (2 Bags) Per Yard SKU: 35103008-81-D | UPC: 842467100790

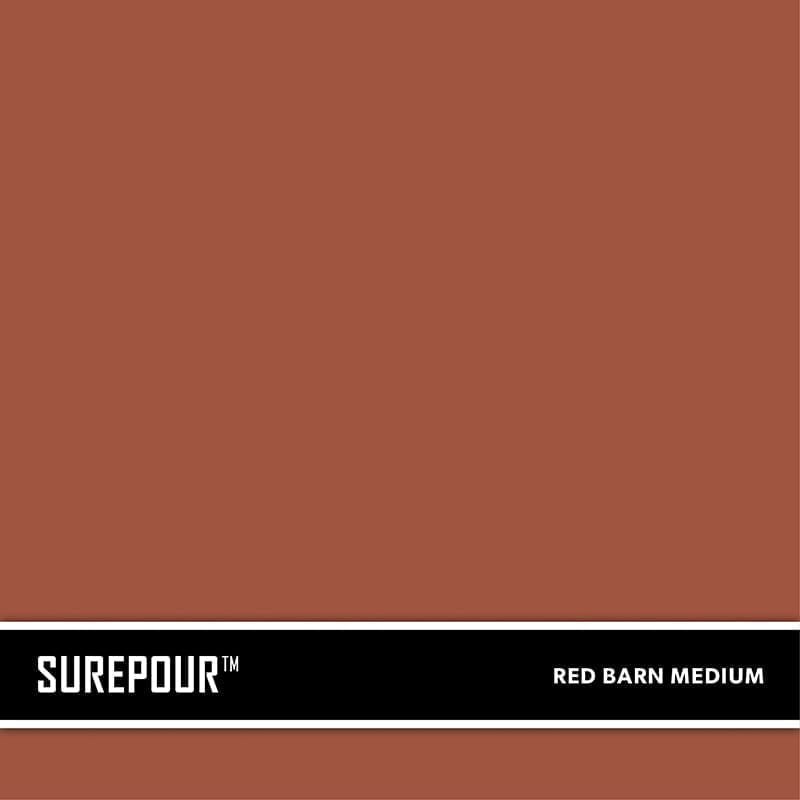

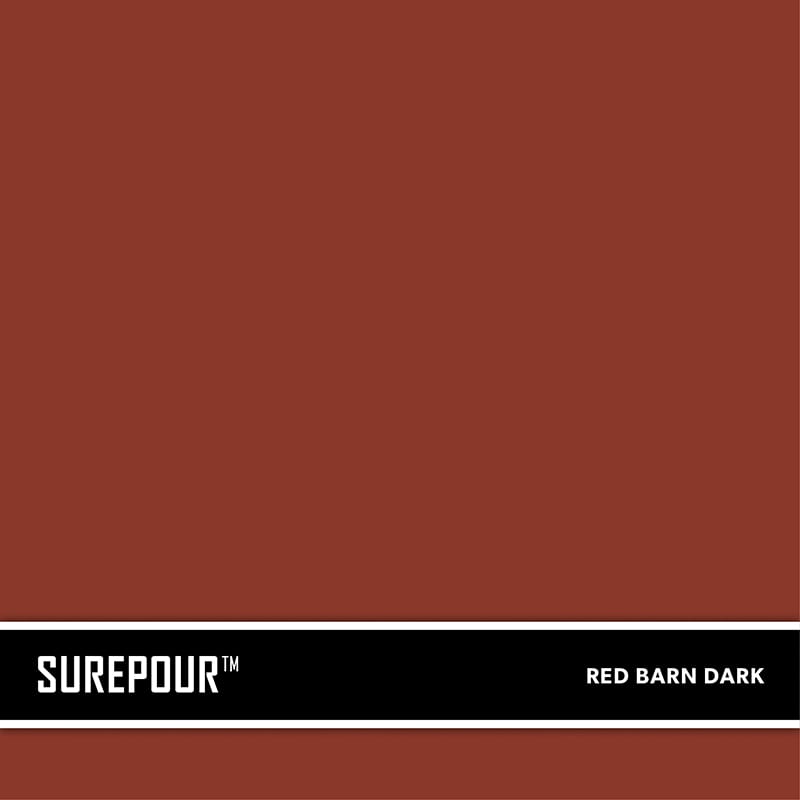

Light Red Barn (1/2 Bag) Per Yard SKU: 35103008-85-L | UPC: 842467100806

Red Barn (1 Bag) Per Yard SKU: 35103008-85 | UPC: 842467100813

Dark Red Barn (2 Bags) Per Yard SKU: 35103008-85-D | UPC: 842467100820

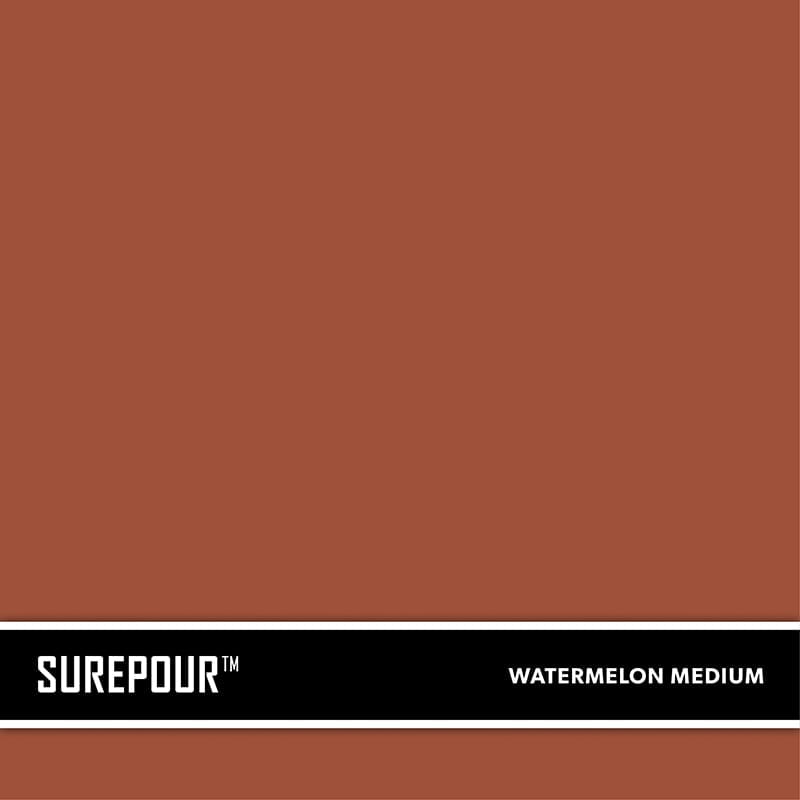

Light Watermelon (1/2 Bag) Per Yard SKU: 35103008-91-L | UPC: 842467100837

Watermelon (1 Bag) Per Yard SKU: 35103008-91 | UPC: 842467100844

Dark Watermelon (2 Bags) Per Yard SKU: 35103008-91-D | UPC: 842467100851

Chocolate (Case of 6) (1 per bag) SKU: 35103009-07 | UPC: 842467100622

Carmel Buff (Case of 6) (1 per bag) SKU: 35103009-73 | UPC: 842467100639

Chestnut (Case of 6) (1 per bag) SKU: 35103009-74 | UPC: 842467100646

Gun Metal (Case of 6) (1 per bag) SKU: 35103009-81 | UPC: 842467100653

Red Barn (Case of 6) (1 per bag) SKU: 35103009-85 | UPC: 842467100660

Watermelon (Case of 6) (1 per bag) SKU: 35103009-91 | UPC: 842467100677

SureCrete's SurePour™ is available in 18 colors. Our 10-pound ready mix fresh concrete colors bags provide the contractor with a light fast, weather resistant, lime-proof, no maintenance finished product. SureCrete Design Products maintain the highest tinting qualities with strength and color material consistency from bag to bag. In our manufacturing plants, color is conveniently packaged in a disintegrating bag that disperses safely and rapidly into the cement concrete batch, making it better than most ready-mix color companies in the market today. Avoid a sign discolorations concrete by sealing your concrete with a high-quality sealer.

Additional information

| Integral Color Options | Light Caramel Buff, Medium Caramel Buff, Dark Caramel Buff, Light Chestnut, Medium Chestnut, Dark Chestnut, Light Chocolate, Medium Chocolate, Dark Chocolate, Light Gun Metal, Medium Gun Metal, Dark Gun Metal, Light Red Barn, Medium Red Barn, Dark Red Barn, Light Watermelon, Medium Watermelon, Dark Watermelon |

|---|